Investing in high-quality ball field netting is crucial for ensuring the safety of spectators and surrounding properties. Facility managers often face unique challenges that require more than standard off-the-shelf netting solutions. Professional-grade materials like twisted-knotted nylon provide the durability needed for long-term outdoor use and heavy impact. Therefore, park directors and stadium managers must evaluate their specific barrier needs before beginning a new season. We focus on providing factory-direct solutions that offer both longevity and aesthetic appeal for high-traffic environments.

Custom Solutions for Professional Ball Field Netting

Every athletic facility presents unique installation requirements that demand specialized dimensions and material weights. Consequently, factory-direct production allows for precise customization to meet the specific safety demands of any sports establishment. Below are three specific examples of how custom-built ball field netting addresses complex containment and protection needs.

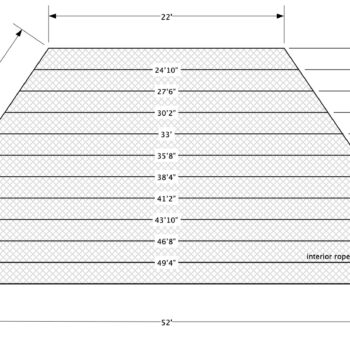

1. Overhead Trapezoid Backstop for Spectator Safety

One notable project involved a custom trapezoidal shaped ball field netting panel designed for an overhead backstop area. This specific design utilized #36 x 1-3/4″ twisted-knotted type 66 nylon to provide superior impact resistance. The panel featured 5/16″ polyester rope bordering along with ten interior ropes for additional structural support. This custom shape ensures spectators remain protected from foul balls while maintaining clear visibility of the game. The production diagram below illustrates exactly how these specific rope placements align with the unique trapezoidal dimensions.

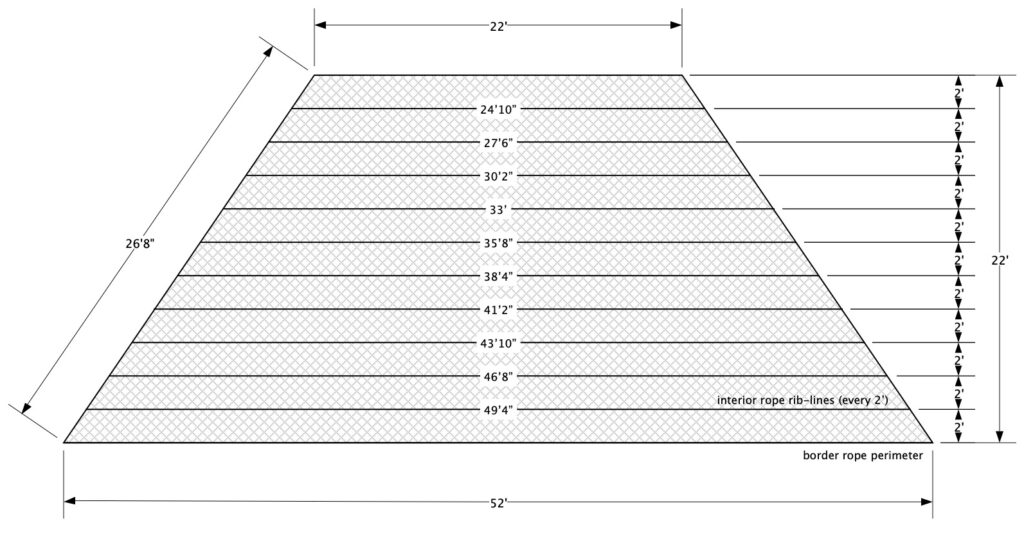

2. Tapered Property Protection Netting for Golf Boundaries

Another essential application for barrier nets is protecting residential properties from errant golf ball impacts. We produced a vertical protection net using #12 x 1″ tarred type 66 twisted-knotted nylon netting. This project required a unique tapered design with specific dimensions to match the customer’s landscape requirements. The tarred finish provides extra weather resistance and durability for long-term outdoor exposure in residential settings. Consequently, the property owner received a durable barrier that blended seamlessly into the surrounding environment and topography.

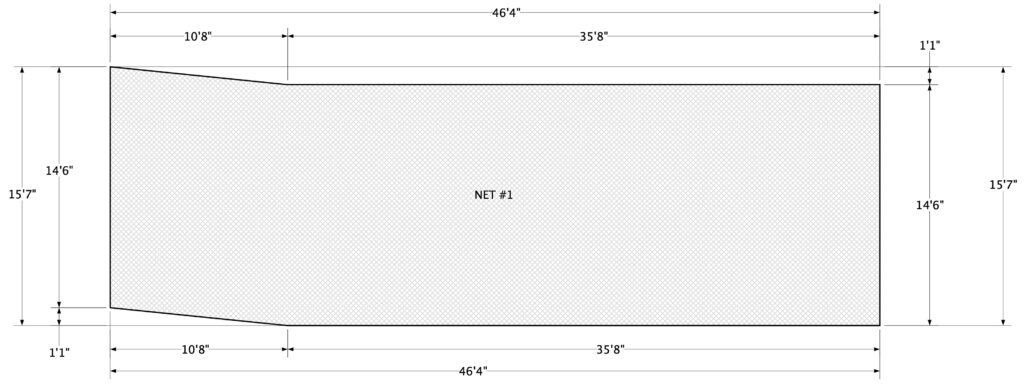

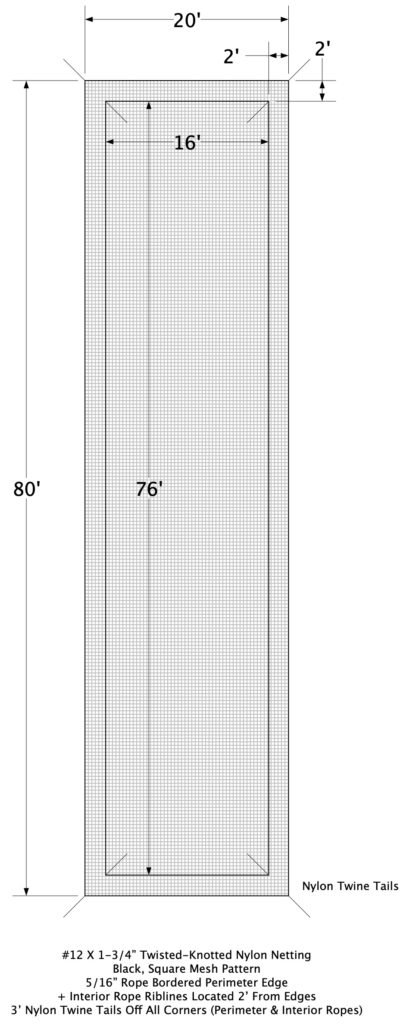

3. Overhead Protection Panels for Multi-Sport Use

Our third example features an overhead protective netting panel measuring 20 feet by 80 feet. The construction uses #12 x 1-3/4″ type 66 nylon mesh in a traditional square pattern for coverage. We incorporated an interior rope running two feet in from the perimeter for specialized mounting needs. This lighter-duty solution effectively blocks various errant balls from leaving the designated field area. The included production drawing highlights how the interior rope adds stability to the square mesh layout.

Selecting the Ideal Ball Field Netting for Your Project

Choosing the right ball field netting requires a balance of material strength and customized engineering specifications. Our factory-direct approach allows us to create precise panels that solve complex safety and containment problems. Investing in reliable netting prevents costly property damage and ensures your facility maintains a professional appearance. We prioritize the use of premium American-made materials to deliver the highest quality results for our clients. Please review our latest production designs to see how custom netting can improve your athletic facility.

Gourock.com specializes in ball field netting panels that are custom made per-order, from premium mesh materials.We work with clients of all volume levels and sizing needs, from professional sports establishments to private individual fields. Always feel free to contact us directly if you have sports netting inquiries or questions – it is our pleasure to assist!

– Josh Grzyb @ Gourock.com Custom Netting